On-site Machining

Overview

Projem’s breakdown service is not limited to highly qualified technicians, first class machinists and a fully equipped workshop facility, but also consists of a vast range of portable equipment; allowing our team the ability to bring the workshop to you. Our pro-active approach through on-site machining reduces plant shut-down time and where possible, eliminates dismantling and transportation costs.

All equipment is well maintained and calibrated through accredited laboratories, to ensure it is intrinsically safe for use in various industries. Our fully equipped portable tooling container, also allows us the ability to have the correct tools on-site and on hand, resulting in a much faster turn around time and cost effective solution.

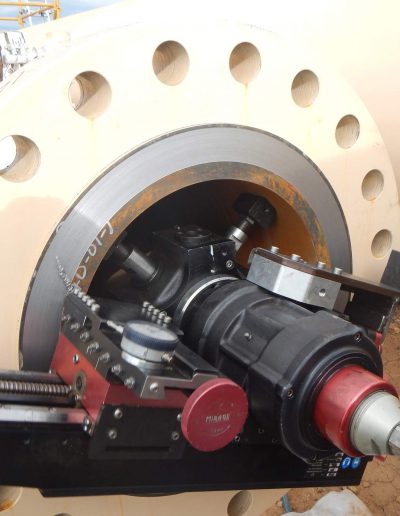

Flange Facing

Projem carries a complete range of flange facing machines to cover flange diameters from 0-2000mm, including RTJ machining capability. Machines available are as follows:

- External Mount 0″-12″

- Internal Mount 2″-24″

- Internal Mount 6″-40″

- Internal Mount 12″-60″

- Internal Mount 24″-80″

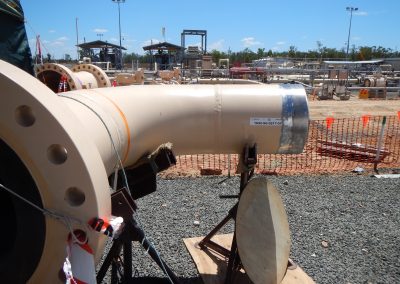

Pipe Cutting & Weld Prepping

Projem can carry out pipe cutting and machining of weld preps on pipe sizes ranging from 100NB to 1200NB. Clamshell machines are available in various sizes and a boring attachment can also be used to match bore pipes to suit fittings. All clamshell machines are pneumatically operated for intrinsic safety and form tools can be supplied to suit any weld prep specification.