Recent Projects

Recent Projects

Our plant shutdown and break down service history for both on-site and in our workshop, include minor and large-scale projects at local, interstate and international levels. We are proud to sustain our goal of zero harm and remaining 100% leak free for bolted joints on-site.

RTA YARWUN – DIGESTION SHUTDOWN UNITS 1-4 (2016-2020)

- Location: Gladstone, QLD

- Principal Contractor: MHPS (2016-2018) UGL (2019-2020)

PROJEM’S SCOPE – Between 8 – 10 Supervisors, Technicians, Tensioning & Torqueing Equipment:

- Unbolting & Bolting of Pipe Work.

- Technical Support in the form of Fitters/Machinist.

- Flange facing repairs including Ring Groove Machining.

- Workshop machining Orifice Plates.

- Manufacture & Supply Isolation Orifice Plates.

- Supervision of principal contractors Plant Services Technicians.

- De-tension studs on all high-pressure vessels and associated pipework.

- Assist with QA on Flange Faces and re-machine if required.

- Assist with assembly and Torque or Tension of all joints.

- Completed with leak free Start Up.

Windsor TRS Upgrade – Gas supply to the greater Sydney region (2017)

- Location: Sydney, NSW

- Principal Contractor: Jemena

PROJEM’S SCOPE ‐ To upgrade the Windsor Trunk Receiving Station’s capacity to meet the forecasted 2023 load of 13,000 scmh @ 3700kPag minimum inlet pressure:

- Supply all fabricated pipe spools.

- All lifting and rigging projects.

- Remove all existing pipework and install new pipework.

- Install all new small-bore pipework (Tubing).

- Complete all structural requirements.

- Commission each Run (2 of).

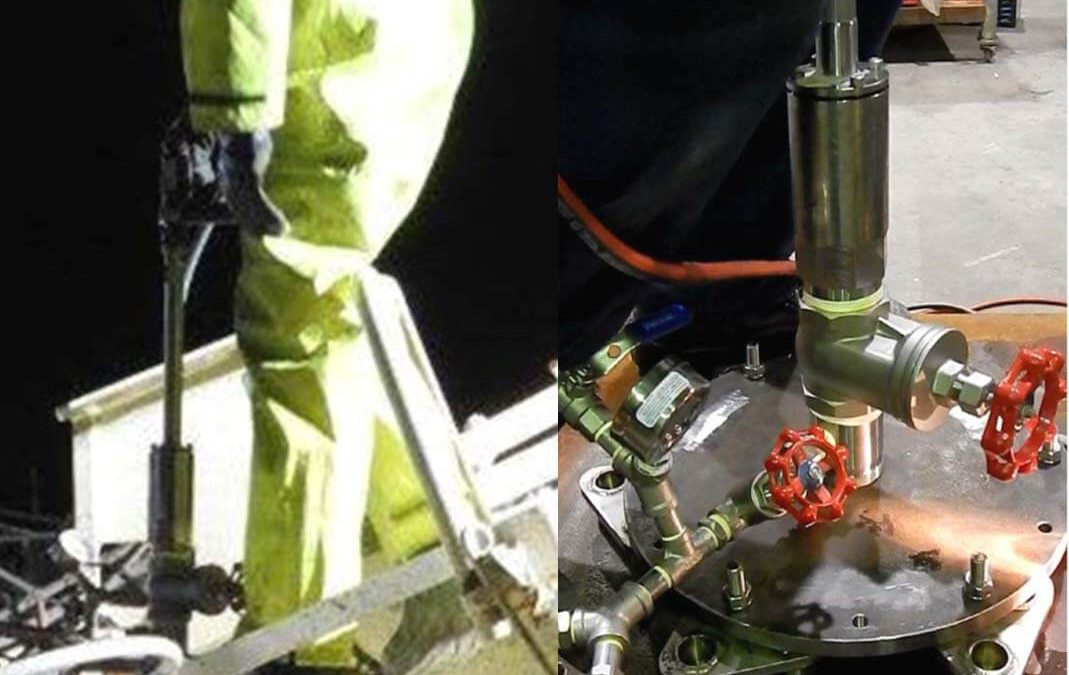

Hot Tap Rail Tankers (January 2016)

- Location: Julia Creek, QLD

- Principal Contractor: Incitec Pivot

PROJEM’S SCOPE ‐ Supply Equipment and Labor to complete 4” Hot Tap on 18 Railway Tankers

- Modify new valves to allow for acid service.

- Design & Manufacture a Hot Tap machine to suit the capability of drilling into Vessels while under Nitrogen purge including installing a ball valve to assist with purge for welding.

- Develop JHA’s & Risk assessments to mitigate the risks associated with drilling into the pressurized vessel that may contain traces of Hydrogen vapor.

- Mobilize to site & performed trial run for all interested parties and confirm risk assessments.

- Drill & tap to suit ¼” BSP hole with small hot tap machine under Nitrogen purge, continue gas monitoring until satisfactory LEL (Lower Explosive Limit) is achieved.

- Prep area to weld 4” stab onto vessel while continuing purging.

- Set up & cut 4” Hot Tap hole with T101 Hot Tap Machine whilst still purging.

- Remove machine and hand to customer for decanting.

Jemena – Moura Meter Station (October 2015)

- Location: Moura, QLD

- Principal Contractor: Jemena

PROJEM’S SCOPE ‐ Supply Equipment and Labor for Installation of New Gas Pipeline

- Engage Piping contractor – To Fabricate and Supply Pipework.

- Removal of redundant pipework.

- Perform Standard Flange Management Tasks – Machining of Flanges as required including insulated gasket faces.

- Install all new pipework.

- Perform leak test on completion of installation of new pipework.

- Sign off & hand over completed project to Client.

APA Pipeline (May 2015)

- Location: Wallumbilla, QLD

- Principal Contractor: Energy Works

PROJEM’S SCOPE ‐ Installation of Pipework for APA. This consisted of removal of NRV at four pigging/pig launcher stations between Wallumbilla Compressor Station through to Ballera. This was to allow for Flow Reversal on the main 18” 900lb gas line.

- Installation of Pup Spools.

- Flange Management i.e. Bolting.

- Machine flanges as required.

- Re-energize pipeline and assist with leak test.

Bechtel PJET (December 2013/2014)

- Location: Gladstone, QLD

- Principal Contractor: Bechtel Australia Pty Ltd

PROJEM’S SCOPE – 8 Technicians Full Time

Supply of Equipment and Technicians to reface damaged flanges before they were sent to the gas projects for Santos, APLNG and QCLNG

- Machining Blinds up to 2mtrs in diameter to achieve ASME standard raised face finish.

- Machining special seals in batches of 100 to suit high pressure valves for the three LNG Projects.

- Flange facing of damaged faces as required workshop/onsite up to 1800mm diameter, both raised face and ring type joint flanges.

GLNG Upstream Project Injune (February to August 2014)

- Location: Injune, QLD

- Principal Contractor: CDJV (Clough Downer Joint Venture)

PROJEM’S SCOPE – 20 Technicians over 7 Months

Supply of equipment and technicians to complete Flange Management and bolting on the GLNG Upstream project. We were involved from well pads to transmission to Gladstone, including PCS‐01, Hub 4 and Hub. All Projem joints were 100% leak free during purge testing:

- Inspection of flange faces to meet ASME standard.

- Development of flange management register for QA.

- Flange facing of damaged faces as required onsite up to 1200mm diameter.

- Tensioning of joints with studs sizes up to 3.1/2”.

- Torqueing of joints using pneumatic and hydraulic equipment up to 25,443Nm.

- Pipe cutting to site fit and repair defect welds up to 1200mm diameter.

- Coordination of hydro testing.

- Drilling and tapping blind flanges.

- Project manage schedule and completions

Santos CSG Compressor Station (July – December 2013)

- Location: Fairview, QLD

- Principal Contractor: CDJV (Clough Downer Joint Venture)

PROJEM’S SCOPE – 6 Technicians for 5 Months

Cutting and machining weld preparations on heavy wall pipe for fabrication workshop delivering pipe spools to the Santos CSG compressor stations at Fairview:

- Use of clamshell machines to suit range from 200NB to 1200NB with wall thickness of up to 50mm.

- Approximately 760 pipes cut and beveled

Rio Tinto Yarwun 2 Project (April to June 2012)

- Location: Gladstone, QLD

- Principal Contractor: Bechtel Australia Pty Ltd

PROJEM’S SCOPE – 2 Supervisors for 6 Weeks

Assist Bechtel with the commissioning of 8 x area 330 filters as part of RTA Yarwun 2 project. Asses defects on filters and rectify as required. Design and manufacture new bolts and conical washers to apply even load on warped flanges. Install and test various seal designs on lids by hydrostatic testing. Provide detailed procedure and pricing to machine Dia. 4500mm flanges to rectify defects:

- Use of large torque equipment to break over-tightened lid bolts.

- Use of Mag base drill to bore clearance on bolt holes in lid.

- Design and manufacture new bolts and conical washers.

- Use of correct guns to torque bolts and torque to correct load.

- Hydrostatic testing of pressure vessel

Rio Tinto Yarwun 2 Project – Area 210 Disc Filters (December 2011 – March 2012)

- Location: Gladstone, QLD

- Principal Contractor: Bechtel Australia Pty Ltd

PROJEM’S SCOPE – 2 Supervisors, 16 Technicians for 4 Months

Area 210 disc filter sectors installed as part of RTA Yarwun 2 project were found to be oversize by 0.03mm on the journals that had to fit into the outlet bore (BSI) Our task was to develop a procedure for repairs and custom build machines to complete work on and off site. Total number of filter sectors 6,660:

- Manufacture test gauges to check tolerances.

- Design and manufacture chamfer tool using pneumatic die grinder.

- Design and manufacture of a machine to linish each of 6,660 filter sectors.

- Asses and repair alignment issues with control heads, gearboxes and bearings.