Flange Management

Overview

An integral part of our success in joint integrity and history of providing leak-free connections, is due to our overall Flange Management processes. At Projem, we understand the importance of achieving leak-free connections and the possible impact on the environment and the economy. Our Flange Management process is tailored to suit the client and sites individual needs, while ensuring all technical data is accurately captured and compiled in a detailed report for reference and future planning.

Our highly experienced technicians are not only qualified in the application of on-site machining and controlled bolting, but also every step involved in the safe and efficient management of the flange from planning, to breaking of joint to flange completion.

What we can offer:

- Mechanical Engineer – Involved in the planning stages to ensure a smooth application and delivery, optimising the desired output and meeting client deadlines

- Technicians – Highly qualified on-site machining and bolting

- Technicians and Team Supervisors

- Equipment – A comprehensive range of site machining and bolting equipment. All equipment has been maintained to meet ISO standards and intrinsically safe for use on various projects. Our portable store container, allows us to have the required equipment on hand, on-site

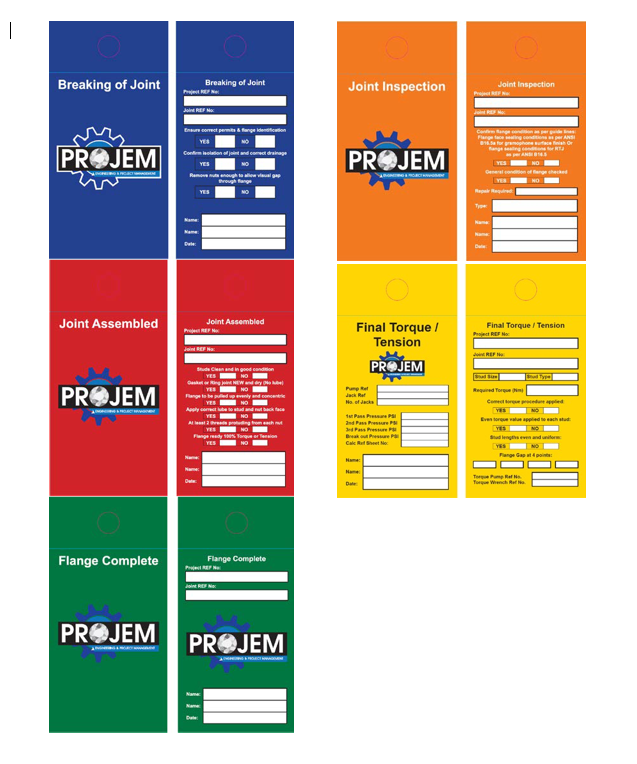

- Projem Flange Management Tags – To ensure the correct processes are performed and vital information captured on each and every critical joint.

- Fully Equipped workshop Facility – If it can’t be machined on site, we have you covered. Our team is backed by a fully equipped workshop facility and first class Machinists

- Flange Management Register – Providing a full history of all technical information on each Joint, referenced to an identifiable number and drawing