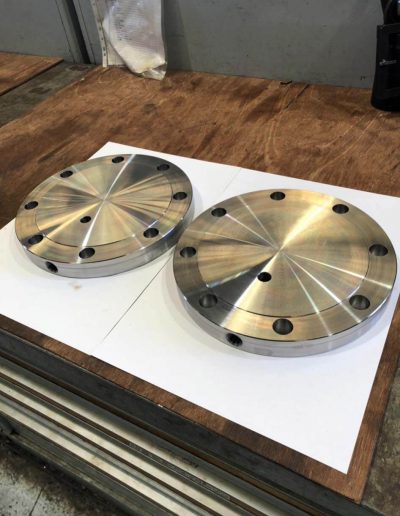

Machining & Fabrication

Overview

PROJEM’s fully equipped workshop facility, allows our team of highly qualified staff to provide specialised engineering and manufacturing services across a diversity of sectors. Our capabilities range from advanced CNC machining, manual machining, welding & fabrication to technical design and drafting services. Delivering these services 24-hours a day to support major industries and smaller projects across the Queensland region and throughout Australia. Our ISO certified Integrated Management System has been implemented to ensure that each job is completed to the highest standard, while also providing a quick turnaround.

Machining

- Okuma CNC Mill/Turn Lathe – Capacity Dia. 350mm x 950mm long with 120mm Y-axis

- Okuma CNC Lathe with bar feeder – Capacity Dia 350mm x 500mm long

- Okuma CNC Mill with 4th axis – Capacity X – 1050mm Y – 560mm Z – 500mm

- Mazak CNC Mill with 4th axis – Capacity X – 1000mm Y – 500mm Z – 500mm

- Kiheung Point U7 Milling Machine Point – Capacity X – 2000mm Y – 1000mm, Z – 800mm

- 3 x Conventional Lathes – Capacity Dia. 900mm swing x 6000mm long

- TOS 100 Horizontal Borer

- Slotter – Internal keyways up to bore Dia. 500mm x 300mm stroke

Workshop

- 4000m2 fully secured industrial allotment with 625m2 of warehouse/workshop and 85m2 of office

- Technical Design & Drafting Services

- Mig, Stick and Tig welding up to 350amps

- Automatic Bandsaws – Capacity 400mm with compound vice

- 20T Punch and Shear

- 10T Overhead Gantry throughout workshop

- 10T, 12T and 20T Mobile Cranes

- 3.5T and 5T Forklifts

- 270cfm Diesel Compressor

- Site Standard Vehicles